Intelligent Mobility for Effortless Operations

360° Safe Obstacle Avoidance, Intelligent Recognition, Self-adjustment, Self-charging

Mobile Robot

Introducing TitanFlow™

TitanFlow redefines how materials move through your facility. Our advanced autonomous mobile robots are designed to streamline workflows, reduce labor costs, and increase productivity — all while adapting to your unique environment.

From manufacturing floors to warehouses and distribution centers, TitanFlow delivers consistent, reliable performance that keeps your operations running smoothly.

Features at a Glance

Key Features

Latent Lifting AMR

The latent AMR has a load range of 0-3000KG, supports various navigation methods such as laser SLAM, QR code, and texture, has multiple safety protections such as safety laser, TOF camera, and safety edge, and has a complete battery management strategy. Adapt to applications such as warehousing, workshop, and 3PL.

- Precise positioning

- Collaborative and efficient

- Multiple security protection

- Modular Design

Forklift AMR

Forklift AMR is based on the design of special forklift truck, realizing a moving forklift (1T to 3T) and stacking forklift (1m to 4.5m). Its characteristics include narrow channel pick-up and release, intelligent sensing, independent pallet identification, high-precision laser SLAM navigation, 360° three-dimensional safety detection, and more. It has been successfully applied in the cargo transfer, stacking and shelving of various industries such as auto parts, new energy, 3C manufacturing, textile, and heavy industries.

- Reliable, Security

- Intelligent Sensing

- Multi-sensing perception

- Strong scene adaptability

Accessories

The efficient and intelligent AMR charging device is uniformly managed by the RCS. The display screen supports fault query, air switch safety protection, bracket adjustment, multiple communication modes, multiple charging modes and other features. Suitable for a variety of AMR equipment models, providing accurate and efficient charging of AMR equipment.

- Accurate Charging

- Flexible Docking

- Safe & Efficient

- 5G Communication

RCS Dispatching Platform

Dynamic adaptation, efficient scheduling and flexible scene adaptability

- Intelligent scheduling algorithm

- IScience Task Assignment Strategies

- IScenario configuration

Features at a Glance

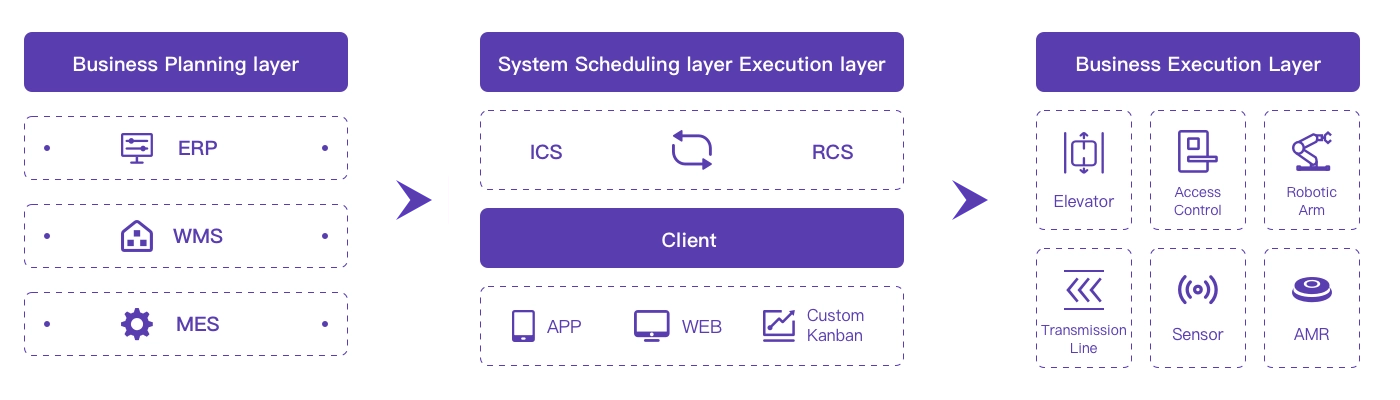

System Scheduling Layer & Client Side

RCS

• Intelligent scheduling: Independently developed scheduling algorithms, dynamically scheduled optimal AMR execution tasks, single server supports scheduling of hundreds of AMR devices, and supports cluster scheduling.

• Path planning: complete the path planning in milliseconds, coordinate the operation of the optimal path, and do not interfere with each other.

• Traffic management: dynamic traffic monitoring, global traffic prediction, real-time optimization of paths; scientific congestion management to avoid traffic jams.

• Task management: intelligent task management, multi-dimensional task priority, multi-strategy management, reasonable allocation of tasks, and provide efficient task execution solutions.

• Autonomous charging: Real-time monitoring of equipment power and system tasks, autonomous scheduling of AMR device charging, no need for manual intervention to avoid affecting the service, abundant charging strategies to meet different use scenarios

ICS

• Seamless docking of the upper layer business system, supporting a variety of call modes, automatically issuing tasks, without manual intervention, reducing the probability of errors.

• Flexibly connect third-party execution equipment, unified and coordinated control, to meet a variety of work processes.

• Multi-system, multi-equipment, task coordination and control, and collaborative completion of upper-level business operations.

Client

• PC: Flexible configuration of tasks, according to the configuration task process to allocate optimal equipment execution.

• Flexibly adjust the system policy configuration and equipment operating parameters according to the customer’s environment.

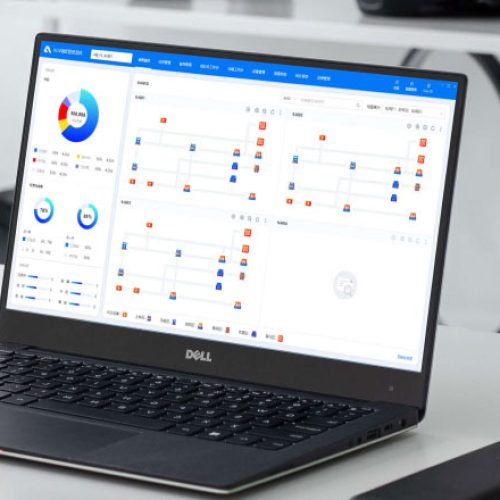

• Real-time monitoring and display of equipment running path, location, status, alarm record real-time statistics, automatic collation and analysis of system operation data, etc.

• APP: The interface is simple and easy to use, to meet the needs of mobile office of handheld.

Features at a Glance

Use Cases

Intelligent Intralogistics solution

TitanSiS introduced the intelligent factory logistics solution. Based on enterprise ERP, MES and other production business systems, the handling AMR can reduce logistics costs by managing material storage along the production line and the optimizing material handling path. This solution also reduces the amount of time operators spend every day on invalid operations (distribution, loading and unloading, placement, unpacking, handover and so on) to significantly improve the production efficiency. It is applicable to logistics and transportation (raw materials, spare parts, work in process, semi-finished products and finished products) in the manufacturing process.